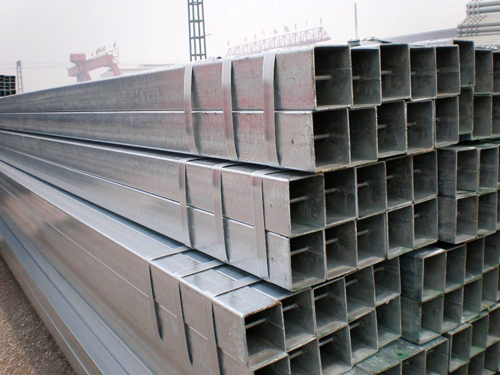

作为一个生产方管的厂家要对方管的各个工艺流程、钢管材质性能有足够的掌握,在客户订购焊管的时候方管和矩形管是客户的选择对象。我们多次提到方管和矩形管的优劣,方管在生产过程中只有管端的尺寸是最严格的的,毕竟方管不同于矩形管,所以在生产方管的时候要注意把口径和管端做到最好,以便于在安装焊接过程中能够方便快捷的施工。对于生产大口径钢管壁厚较薄的钢管的时候要注意加固或者对钢管做支架,以防止方管在运输过程中出现椭圆或口径变形。对于方管来说口径的准确尺寸是最重要的,其次要注意的是方管焊口不要咬边,要把卷制好的钢管的两个焊边对齐对平,焊接出来的钢管才能漂亮、规范。其次要注意的是方管的直度,方管的直度不但影响方管整体的外观最主要的是影响后期施工焊接。

As a manufacturer of square pipe, we should have a good command of each process and material properties of square pipe. When customers order welded pipe, square pipe and rectangular pipe are the customers'choices. We have repeatedly mentioned the merits and demerits of square and rectangular pipes. In the production process, only the pipe end size is the most stringent. After all, square pipes are different from rectangular pipes. Therefore, we should pay attention to the best caliber and pipe end when producing square pipes so as to facilitate the installation and welding process. For the production of large diameter steel pipe with thinner wall thickness, attention should be paid to strengthening or bracketing steel pipe to prevent ellipse or caliber deformation of square pipe during transportation. For square pipe, the exact size of the caliber is the most important. Next, we should pay attention to the square pipe weld without undercutting. We should align the two weld edges of the rolled steel pipe, so that the welded steel pipe can be beautiful and standard. Secondly, attention should be paid to the straightness of square pipes. The straightness of square pipes not only affects the overall appearance of square pipes, but also affects the later construction welding.

管理员

该内容暂无评论